Vapor Phase Carbon Adsorption Systems

Vapor Phase Carbon Adsorption Systems are designed to remove certain gaseous contaminants, including Dioxins/ Furans, Hydrogen Sulphide, Hydrogen Chloride, Ammonia and Mercaptans.

Branch Environmental Corp. offers a Deep-Bed design that may be used as part of a new pollution control train or system, or as a retro-fit unit to be added to an existing system.

The Construction

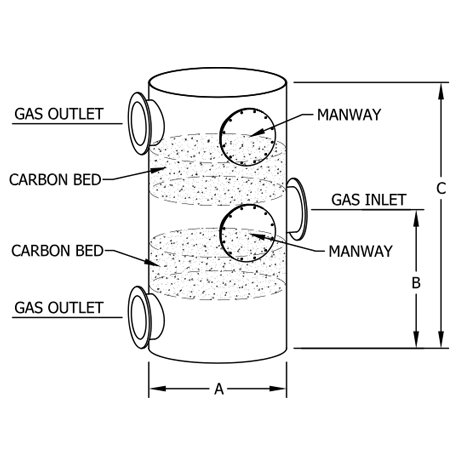

The construction of the shell and internal supports of the Deep-Bed Vapor Phase Carbon Adsorption System are fabricated of corrosion resistant fiberglass. Access man-ways are provided for each bed of activated carbon, for routine inspection and replacement. Lifting lugs and hold-down lugs are provided.

The Process Air Stream

The process air stream, at a temperature up to 140° F (60° C), enters the Deep-Bed Vapor Phase Carbon Adsorption System between two horizontal beds of selected activated carbon. The air stream separates, flowing through the upper and lower beds of activated carbon, where the contaminants are removed, prior to the air being discharged from the system.

Typical Removal Efficiencies

| Contaminant | Removal Efficiency* |

|---|---|

| Dioxins/Furans | 95%–96% |

| Hydrogen Sulphide | 99% |

| Hydrogen Chloride | 99% |

| Ammonia | 99% |

| Mercaptans | 99% |

Numerous types of activated carbon are available, including pelletized, granular, powdered, impregnated, virgin and reactivated, made out of several different materials such as coal, coconut shell and wood. Experience determines the optimum selection of activated carbon for each specific application.

Benefits

Benefits of the Deep-Bed Design

Can be added to an existing pollution control system as a final stage for removal of certain contaminants. Made of corrosion resistant fiberglass material for long service. Compact modular design for easy and economical installation. Various types of activated carbon available for different applications.

| Model No. | CFM (N/m3/hr) | A (mm) | B (mm) | C (mm) | Gas Inlet ID (mm) | Gas Outlet ID (mm) |

|---|---|---|---|---|---|---|

| 48C-2(3) | 1588 (2700) | 4' (1220) | 6' (1900) | 12' (3800) | 10" (250) | 6" (150) |

| 66C-2(3) | 2941 (5000) | 5'5" (1680) | 6'-6" (2050) | 13' (4100) | 15" (375) | 10" (250) |

| 72C-2(3) | 3529 (6000) | 6' (1840) | 7' (2150) | 14' (4300) | 16" (400) | 10" (250) |

| 78C-2(3) | 4118 (7000) | 6'5" (1980) | 7'6" (2250) | 15' (4500) | 18" (450) | 12" (300) |

| 108C-2(3) | 8235 (14000) | 9' (2750) | 7'8" (2400) | 15'6" (4800) | 24" (600) | 18" (450) |

| 120C-2(3) | 9765 (16600) | 10' (3050) | 8' (2500) | 16' (5000) | 24" (600) | 18" (450) |

| 144C-2(3) | 14118 (24000) | 12' (3660) | 8'10" (2700) | 17'6" (5400) | 30" (750) | 24" (600) |