Packed Towers

Packed Towers are used for gas absorption including acid gases such as S02, HCl and others. Packed Towers can also absorb solvents such as Alcohol and gases such as Ammonia. Almost any water soluble chemical can be removed from the gas using a Packed Tower.

Packed Towers can also be used to remove trace quantities such as removing odors including Hydrogen Sulfide.

This type of scrubber can also be used for cooling gas, aeration and any other application where transferring from a gas to a liquid is required.

Branch scrubbers are custom designed to fit your specific application.

- All performance levels are guaranteed.

- Virtually any material of construction is available.

- Complete packages with all components including controls, control panel, fans and pumps for a complete single source responsibility.

- Shop fabricated units up to 50,000 cfm / 8,500 m3/h. Larger units are available using field fabricated designs.

Principle of Operation

Packed columns are used for many purposes including gas absorption.

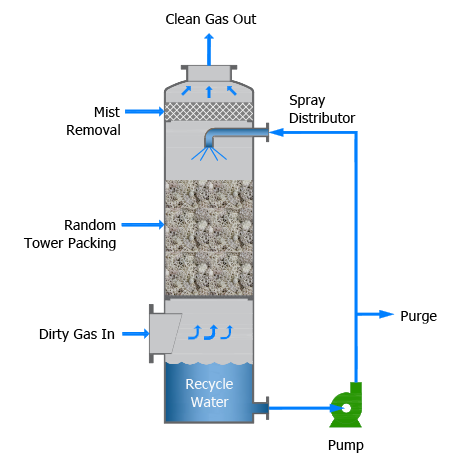

The gas and liquid contact is continuous. The performance can be improved by increasing the height of the packing. The random material (packing) inside keeps the gas and liquid in contact. More contact time can be achieved by extending the bed of packing.

The liquid flows down over the surface of the packing and the packing creates a mixing action between the gas and liquid. The most efficient design is a Counterflow Column where the gas moves upward and is cleaned while the clean liquid flows in the opposite direction picking up the contamination.

Components

The Packed Column consists of a bed of either random or structured media. Most commonly, random material is used to create the most turbulence and mixing action. By constantly breaking the droplets apart the liquid and gas create the most contact and performance. Keeping the column large enough keeps the pressure drop low and minimizes operating cost.

There are many different types of packing. Branch Environmental will design based on the specific application and can use virtually any supplier for this packing material. The material of construction is either metal or plastic depending on the temperatures and gases to be absorbed.

Liquid distribution is important. In some designs a spray distributor is more than adequate. For other applications, a special distributor tray is required. Your design will include the lowest cost configuration that will assure your tower works correctly.

For most applications, where corrosion is an issue a Packed Column will be the lowest cost choice for many requirements.

Pressure drop will be low.

Years of experience allow us to assure the unit will work correctly.