Jet Venturi Scrubbers

Jet Venturi scrubbers can remove dust and gas simultaneously. Their advantage is the ability to handle high concentrations of gases such as Chlorine or other water soluble gases. In many applications, the Jet Venturi can be used without any additional fan.

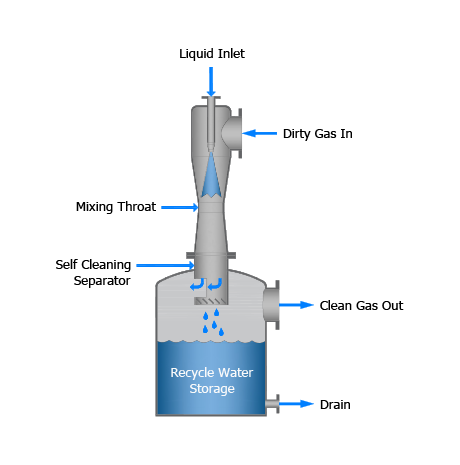

Jet Venturi scrubbers use the energy from the liquid sprayed into the Venturi to create a pull on the gas drawing it into the scrubber. The gas and liquid are then mixed in both the spray section and in the high velocity Venturi throat.

There are many applications for Jet Venturi scrubbers. One example is emergency systems where a gas leak might occur. The Jet Venturi can rapidly pull the gas eliminating any need for a fan, provide a high liquid recycle rate for good contact with a large amount of vapor. Chlorine emergency scrubbers and ammonia storage emergency scrubbers are examples of this kind of application.

Jet Venturi scrubbers are also used in combination with other designs such as the Packed Tower scrubber to provide a 2 Stage approach where high concentrations of gases are present and a very high efficiency is required. Any Venturi design is limited in contact time. It provides a good initial scrubbing action but may not produce the 99% or even 99.9% efficiency required in many newer regulations. However by using the Jet Venturi, most of the heat and gases can be absorbed first making the Packed Tower design practical and much lower in cost.

- All performance levels are guaranteed.

- Virtually any material of construction is available including Fiberglass, Stainless Steel, special Alloys, Teflon lining and others.

- Complete packages with all components including controls, control panel, fans and pumps for a complete single source responsibility.

- Shop fabricated units up to 60,000 cfm / 100,000 m³/h. Larger units are available using field fabricated designs.

Principle of Operation

The Jet Venturi scrubber is similar to an Ejector or Eductor. That is, it has a spray nozzle which creates a high velocity of one fluid, typically water. In the Fume scrubber, the second connection on the Venturi is for gas. The gas can be air with dust or fumes. It can be process flow such as fuel gas in a synthetic fuel plant.

The wet scrubber will handle dirty gas streams by mixing water or water solutions with the air or gas and transferring the solids or soluble gases to water.

Gases are often neutralized, but not necessarily. For example, Hydrochloric acid can be converted over to Sodium Chloride, “table salt”. Particles can be captured and separated out of the water phase.

Scrubbers are especially suitable for applications involving high levels of gases, simultaneous gas, solid removal, and corrosive services.

Branch Environmental supplies custom built scrubbers and systems for air pollution control. From small units to large custom designed units, you receive competitive pricing with the highest reliability and assurance it can work right the first time.

- Units can be fabricated from virtually any material of construction since we have the capability to supply Fiberglass, Dual Laminate, Stainless Steel, special Alloys and other materials.

- Units can be built to shop standards or special codes including ASME RTP-1 or ASME Section VIII Division 1 depending on the application.

Branch Environmental provides the capability of a complete system – not just a scrubber. We can provide a scrubber alone if you prefer or a packaged system incorporating all the components necessary for a complete installation.